Mechanical Systems

In matter of mechanical installations the BIM technology offers many possibilities: the simple 2D drawing of a project leaves room for a large and detailed modeling that interacts with the design development. Given the relevant dimension of the single components (ducts, machines, conduits, etc.), the problems regarding the interferences (which is one of the major critical issues in designing of this type of systems) are directly addressed during the modeling phase, greatly facilitating the future construction on site.

Furthermore, the possibility of coordinating and processing all the various phases of the project (calculation and graphics) with only one software allows to considerably reduce the working time, without affecting the quality of the finished product.

The cooperation with other calculation software, which previously were used separately, makes now the work even more effective.

The most important aspects of the design of mechanical systems in BIM are:

Energy Model

Like any building energy performance calculation program, with BIM software (in our case, Autodesk Revit) it is possible to assess the thermal loads necessary for the sizing of the air conditioning systems and the verification from the beginning of the assumed performance by the designer.

For more detailed information on this topic, refer to the relative page of the Revit software.

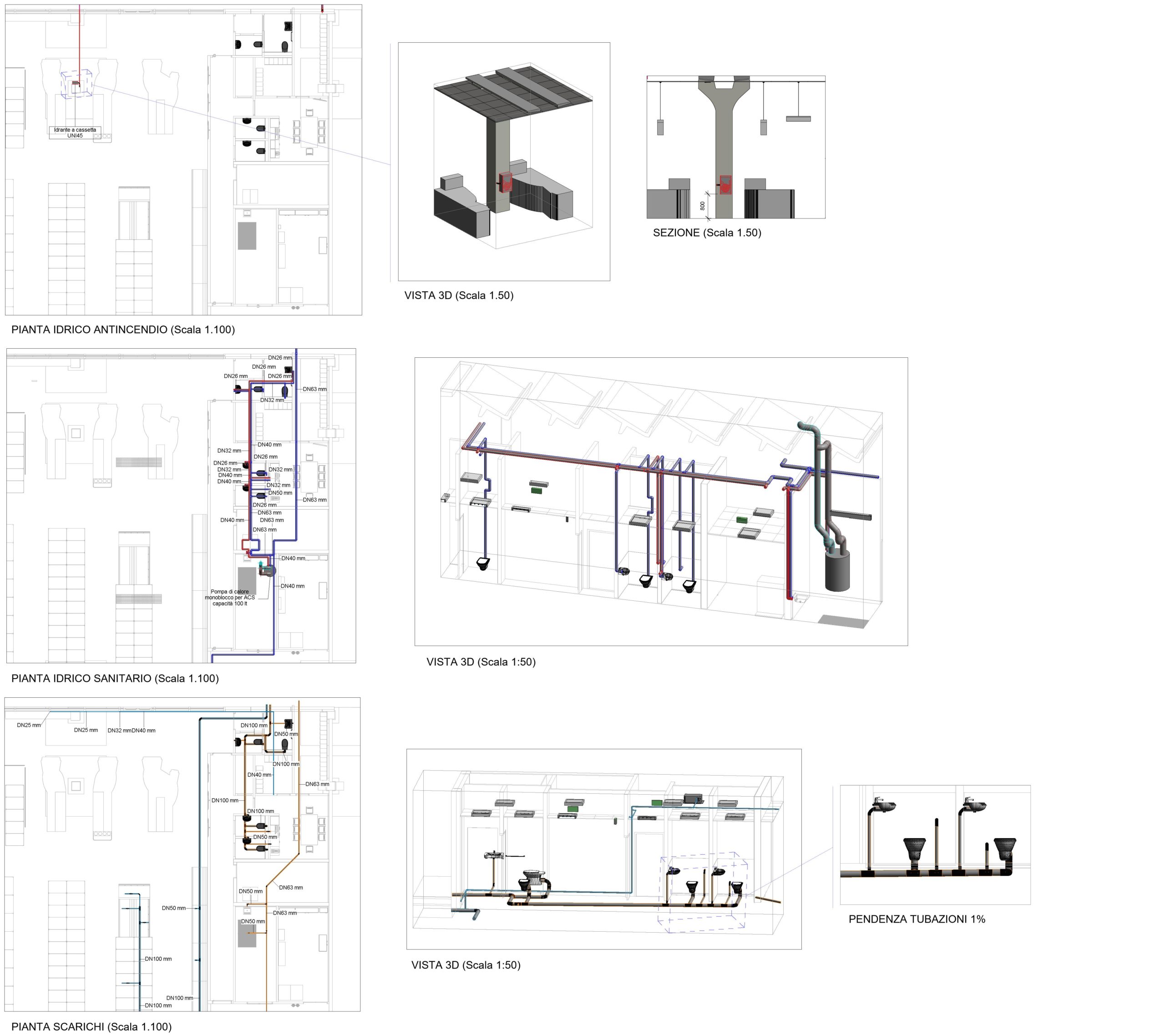

Fire Protection System

This system has the same functions as the other duct/pipe systems. Among the most important ones there is the possibility to navigate in the virtual environment, which allows the designer to view the building in every planning stage and resolve any incompatibility with any other component in real time.

HVAC Systems

Air conditioning and ventilation systems are the systems that benefit most from the use of BIM design, thanks to the greater interaction between modeling and design.

The sizing of the distribution components (pipes and ducts) can be carried out automatically, by setting specific parameters, such as fluid speed, pressure drop or both in combination. In this way, the design phase supports the modeling phase and substantially halves the working times.

In addition to that, it is very useful to have in the software a whole series of options relating to the distribution network, as:

- System classification (supply air, return air, etc.)

- Parameters (air velocity, pressure drop, etc.)

- Type (round, rectangular, etc.)

- Material (galvanized steel sheet, copper, etc.)

- Machines and ducts height

The remarkable realism of the components also allows a reduction of errors in assessing the system dimensions.

For more details, see the Revit page.

Sanitary and Domestic Cold/Hot Water Systems

Also for these systems BIM offers some advantages similar to HVAC system, such as having a range of properties that can be directly set in the software:

o System classification (Sanitary, Domestic Cold Water, Domestic Hot Water, and Other)

o Parameters (up/down slope, slope value, etc.)

o Type

o Material (polished stainless steel, High-density polyethylene [HDPE], etc.)

o Pipes and Components Installation Height